In this short but comprehensive video, we offer a close-up of how the horizontal glass edging machine works. This will give you a complete picture of all its functionalities and give you a better understanding of how it can help you in your daily production process.

MACHINE DESCRIPTION

The BR230 belt grinder can grind all shapes of glass, whether they are circles or classic rectangular or square shapes.

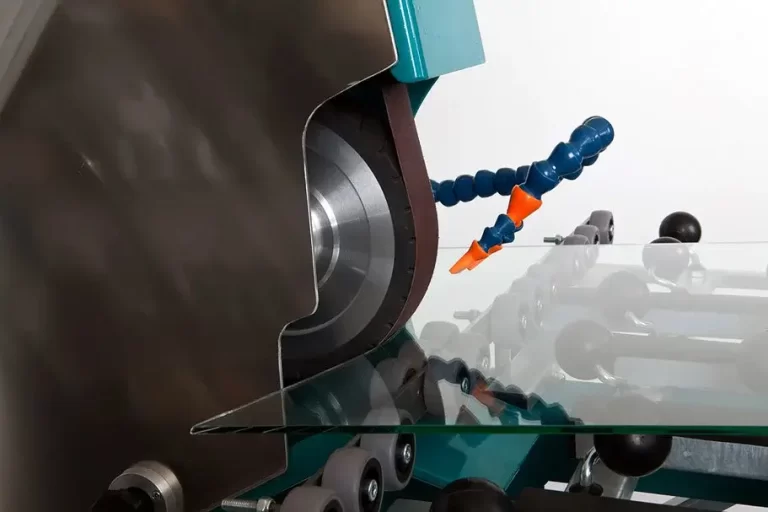

The grinder has a drive roller which drives the motor and a 230mm diameter rubberised contact roller which is in contact with the worked edge of the glass.

With a patented maintenance-free system housed in the machine’s column body, the contact roller can be tilted above the glass level by simply moving the lever towards itself and grinding at a 45-degree angle.

You can adjust the amount of removal of different glass thicknesses simply thanks to the lever that is part of the whole mechanism.

The roller can be brought into the front position by pulling the lever towards you using the „pen mechanism“. The operation of this tilting is very fast and efficient, as is the regulation of the glass edge removal in the range of glass thicknesses 3-12mm.

The belt is changed by means of a tension lever, which, when released, causes the belt to sag between the rollers, allowing the belt to be quickly changed to a different grit according to the desired quality of the glass edge.

Movement on the table work surface is ensured by quality rubberized rollers of the English manufacturer, as well as by the time-tested drive units of the SIEMENS brand.

The grinder is equipped with a water pump that ensures water circulation, which then flows back into the collection container, thus forming a closed water circuit and no need for connection to the water supply.

We treat the structure with galvanic/hot-dip galvanizing and comaxid powder coating.

The complete production of the machine takes place in the Czech Republic in our workshop, in the case of parts that we are not able to produce at home, we use time-tested suppliers.

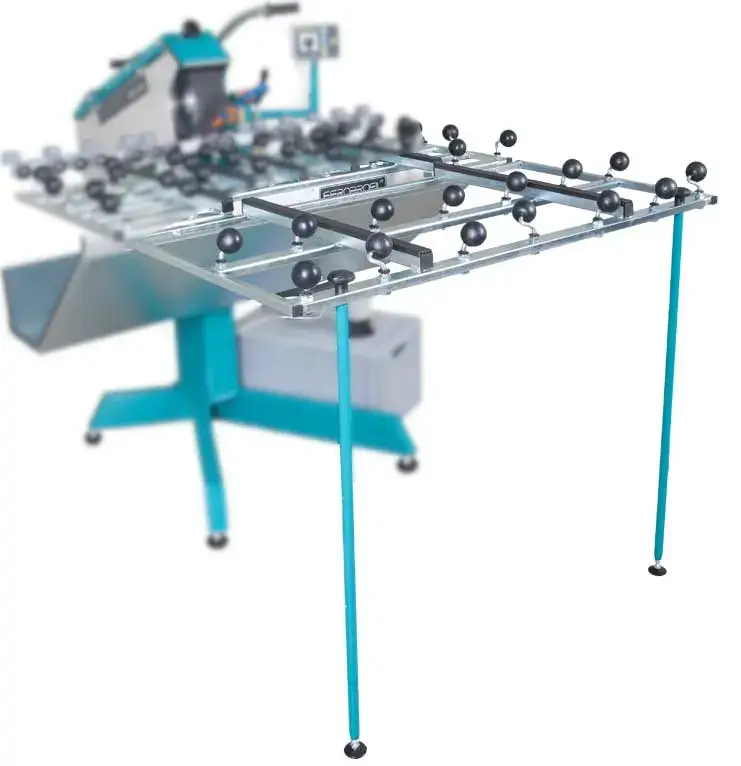

The machine can be equipped with additional equipment such as additional rollers for processing atypical glass dimensions (internal radii, curves, copilites, etc.). Or also front and side extension tables for grinding larger glass formats.

In case of wear or damage to the grinding machines and their parts, we can offer you all spare parts.

TECHNICAL PARAMETERS

MOTOR

1,1 kW , 1400 rpm

El. connection

3 x 380V, 50/60Hz

Dimension of grinding belt

100 / 1830mm

Belt speed

12,4 m/s

Contact cylinder diameter

230mm x 100mm

Dimensions W/H/D

1240 x 1600 x 1500mm

Maximum load of the work table

140 kg

Machine weight

350 kg

Are you interested in our machines?

If you have any questions or need more information, please do not hesitate to contact us. We are here for you and will be happy to prepare a detailed quotation for you. If you need any further assistance, we will be happy to answer all your questions.

OPTIONAL ACCESSORIES

SIDE EXTENSION OF THE TABLE

Ideal for working with large glass

FRONT EXTENSION OF THE TABLE

Ideal for working with large glass

ADDITIONAL CYLINDER

For grinding internal radius