In this short but comprehensive video, we offer a close-up of how a vertical glass drilling machine works. This will give you a complete idea of all its functionalities and give you a better understanding of how it can help you in your daily production process.

MACHINE DESCRIPTION

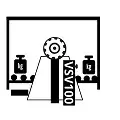

Our vertical glass drilling machine is equipped with a frequency converter for infinitely variable drill speed control, a motorised loading bar lift with a load capacity of up to 180kg, digital Y-axis metering and precise manual control via a control wheel for setting the final position with an accuracy of 0.1mm.

The drill has a water pump that ensures water is circulated, which then flows back into the collection vessel, forming a closed water circuit and no need for a water connection.

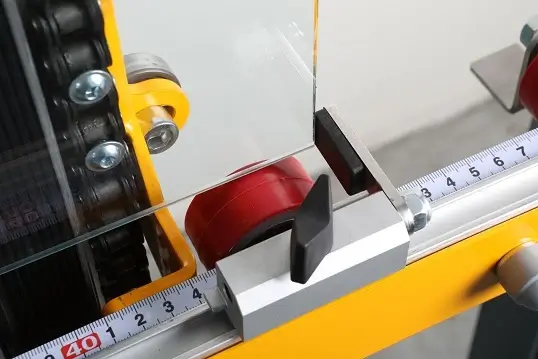

The X position is adjusted by manual locking of the side stops according to the calibrated meter.

Thanks to the tilting pressure plate and the removable pressure plate, drill bits are changed only from the front of the machine. You can therefore place the machine up against a wall in your workshop and save both space and operator time when changing drill bits. The depth of the machine is only 960mm.

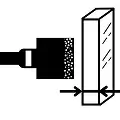

The most important advantage of the drill is the perpendicular drilling to the glass due to the linear drill head design. Use the ergonomic lever to control the drilling of both the rear and front drill heads.

The stop system for adjusting the drilling depth of both the front and rear drill heads is operated only from the front of the machine above the control panel. This system can accurately adjust the drill hole interference within the thickness of the drilled glass, eliminating hole fraying and maximizing mechanical cleanliness.

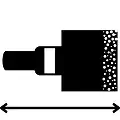

With a large footprint of up to 900mm and a large sturdy support structure, you can drill even large formats of glass.

The complete production of the machine takes place in the Czech Republic in our workshop, in the case of parts that we are not able to produce at home, we use time-tested suppliers.

For drilling oversized glass formats, we can extend the support structure both in height and width.

In case of wear and tear or damage to drills and their parts, we can offer you all spare parts.

TECHNICAL PARAMETERS

MOTOR

1,1 kW , 550 – 1400 rpm

El. connection

3x400 V (1x230 V, 3x 230V), 50/60 Hz

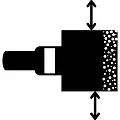

Thickness of drilled glass

3 - 20 mm

Drill diameter

3 - 100 mm

Length of drill bits

75mm

Unloading

900mm

Minimum dimension of drilled glass

110 x 50 mm

Maximum load loading rails

180 kg

Dimensions W/H/D

3024 x 2297 x 998mm

Weight of the machine

380 kg

Are you interested in our machines?

If you have any questions or need more information, please do not hesitate to contact us. We are here for you and will be happy to prepare a detailed quotation for you. If you need any further assistance, we will be happy to answer all your questions.

OPTIONAL ACCESSORIES

DIGITAL METERING

For easier control of the motorised stroke of the loading bar.

SIDE STOPS

Ideal for mass production.

HEIGHT EXTENSION

Height extension of the support structure for the possibility of drilling larger glass formats.